The importance and challenge of consistent annotations

Making sure that we annotate all significant turbine blade damage is obviously important when it comes to making repair and maintenance decisions. What’s less obvious, is how important it also is to annotate that damage in a consistent and repeatable manner.

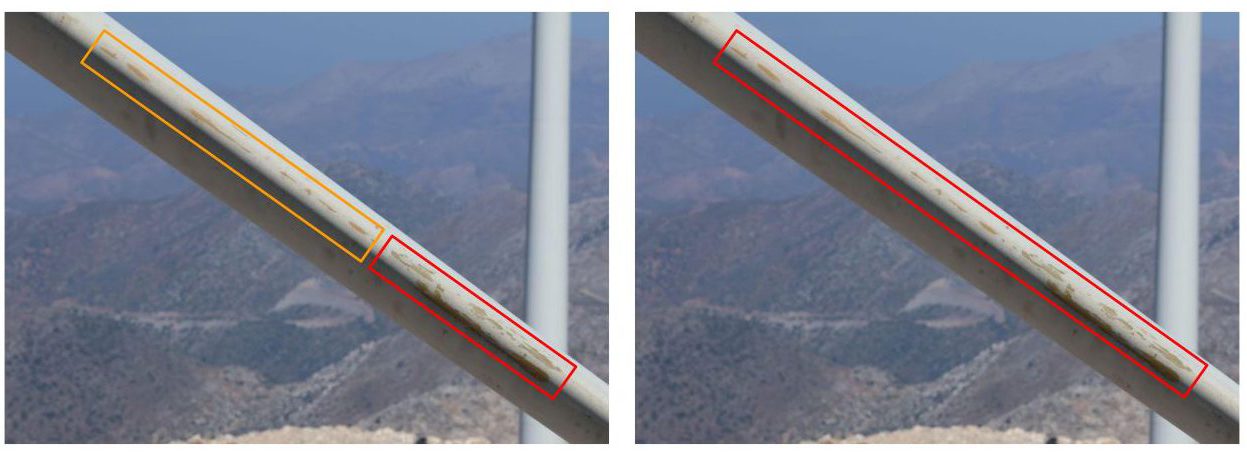

The challenge that we face is that the same region of damage can very easily be annotated in different ways. For instance, leading edge erosion often runs semi-continuously along much of the length of a blade. Knowing when and how to break that damage up into distinct regions is difficult and subjective. You can see an example of this is in the image below, where leading edge erosion has been (a) separated into two regions of damage and (b) all grouped into a single annotation.

So, why do we care? Annotating damage consistently across multiple inspections (over numerous years) allows us to properly track the progression of that damage over time. We can use that information and the rate of progression to help make better repair and maintenance decisions. For instance, if we know that the severity of a particular region of damage has increased quickly over the previous O&M period, then we may want to prioritise that repair.

In the same way that we want to link damage across different inspections, we also need to be able to match annotations from multiple perspectives. If we are inconsistent in our annotation strategy and unable to match those different perspectives together, we will overreport the true amount of damage on the blade. By correctly annotating and matching, we both correctly report the amount of damage and also have the best possible information to help us make repair decisions.

Consistent annotations add long term value to inspection data. Human annotations can be quite inconsistent by nature so there is a risk of reducing the value of the database you are creating.

It makes it more difficult to review and track the health of blades and the fleet as a whole and will ultimately lead to significant deviations in repair spend and budgeting. Investing in better, consistent annotation adds value to that database and ultimately allows you to optimise your blade repair and asset management strategy.

Our data processing pipeline and underlying AI algorithms, which we have been developing for more than 5 years, help us generate consistent annotations (matched across perspectives and inspections). These are coupled with a system for recording, tracing and referring back to annotation information. The data is only valuable if it is easy to access and leveraged appropriately. We provide the tools that allow you to extract the most value from your inspection data.