Blade repair procrastination: Can you really afford it?

Owners and OEMs (Manufacturers) must establish priorities for repairing damages, as budget constraints prevent repairing everything at once. However, what is the cost of delaying repairs until next season?

While the impact may seem insignificant on an individual basis, the cumulative effect of unrepaired damages can be substantial when considering the overall figures.

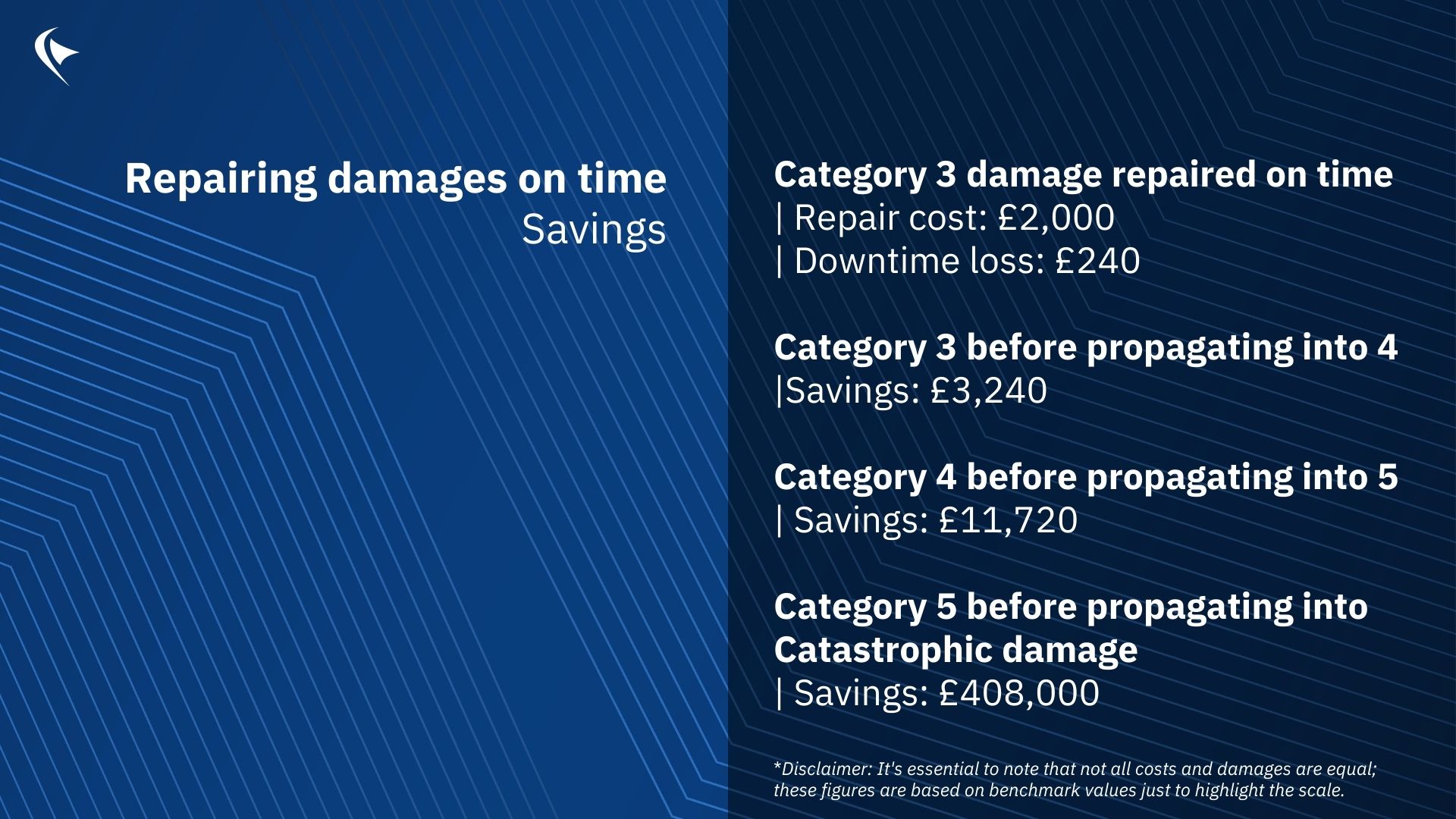

Disclaimer: It’s essential to note that not all costs and damages are equal; the following figures are based on benchmark values just to highlight the scale.

Every year, between 5% to 30% of damages progress to the next stage. Consider the cost escalation:

Category 3 damage repaired on time

| Repair cost: £2,000

| Downtime loss: £240

Category 3 propagated into Category 4

| Repair cost: £5,000

| Downtime loss: £480

| Additional Budget Requirement: £3,240

Category 4 propagated into Category 5

| Repair cost: £10,000

| Downtime loss: £7,200

| Additional Budget Requirement : £11,720

Category 5 propagated into Catastrophic damage

| Repair cost: £400,000

| Downtime loss: £25,200

| Additional Budget Requirement: £408,000

*Assumed 20% capacity factor, £50/MWh, and 2 MW WTG.

Whether due to budget limitations or missed detection, some damages will inevitably evolve, resulting in significantly higher repair costs than if addressed promptly. While repairing all damages would be ideal, prioritising repairs based on their potential impact on revenue is crucial, at least as crucial as not missing any damage particularly when dealing with hundreds or thousands of blades. Our AI and our Advanced Analytics can help you prioritise damage repair effectively.

Want to learn more? Let’s talk.